Leiton Inspire Pack

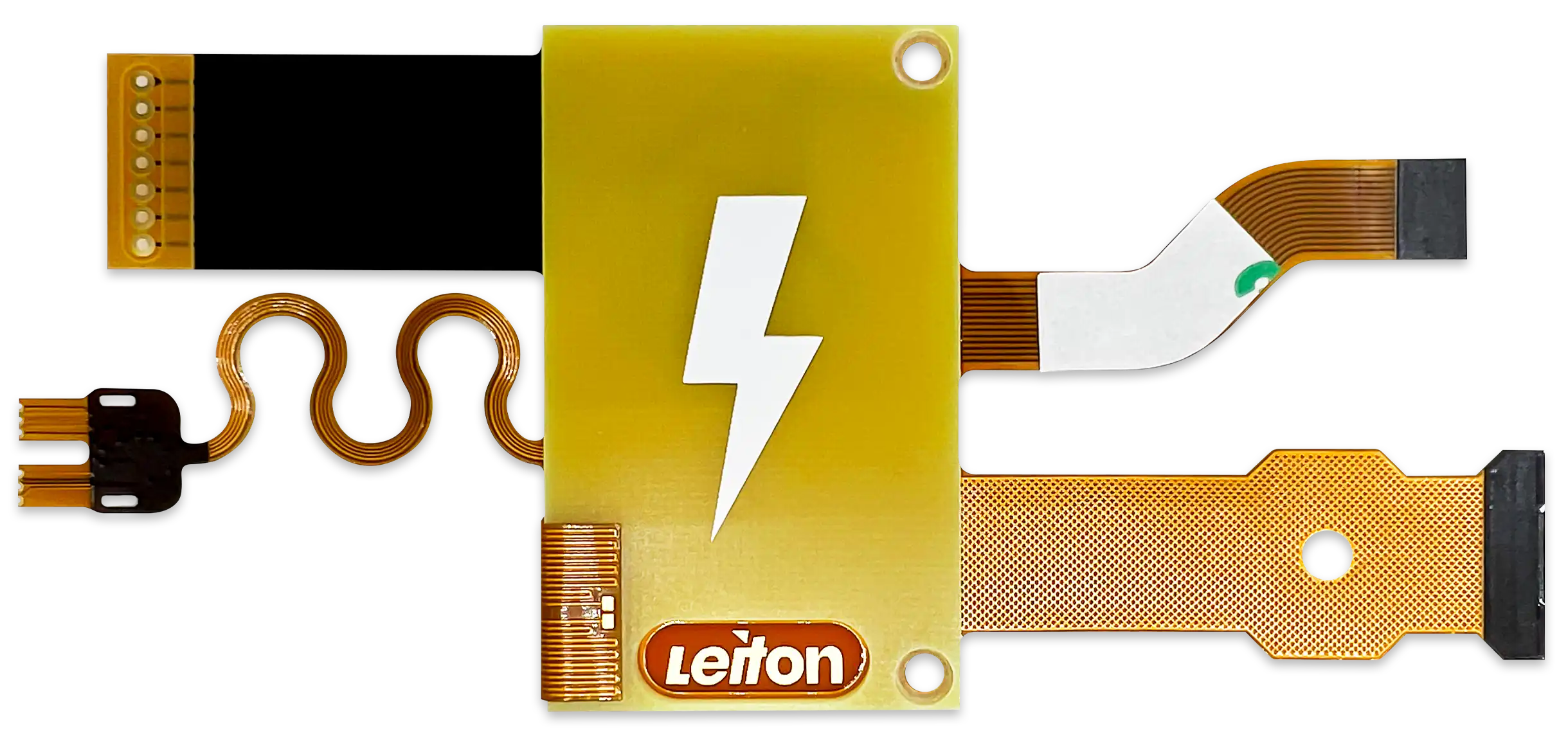

If you don't have one yet, get the Leiton Inspire Pack, featuring our fancy Inspire Board and a stylish laptop sticker. And if you already happen to have one, collect the latest version.

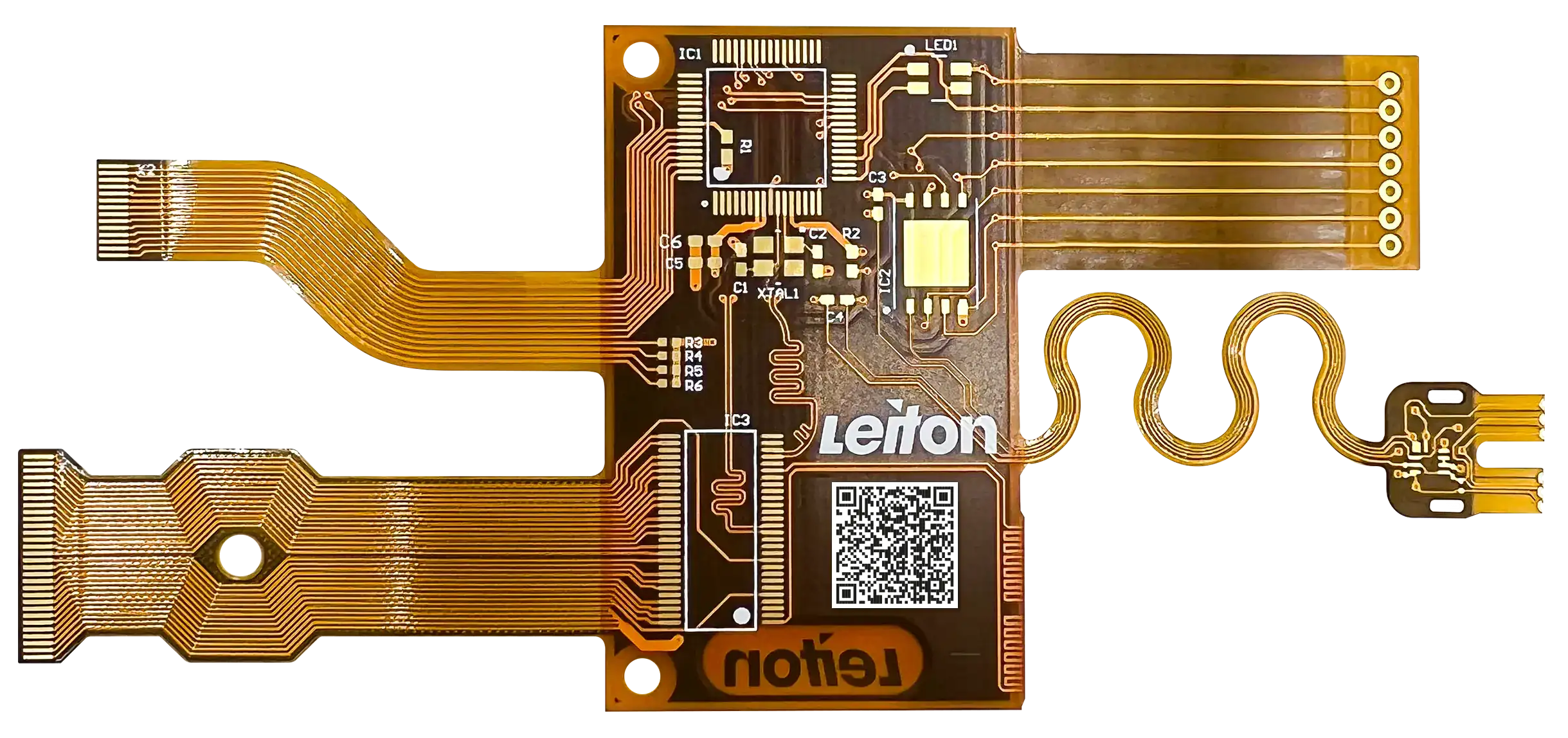

Inspire 3000 XT Board

Features

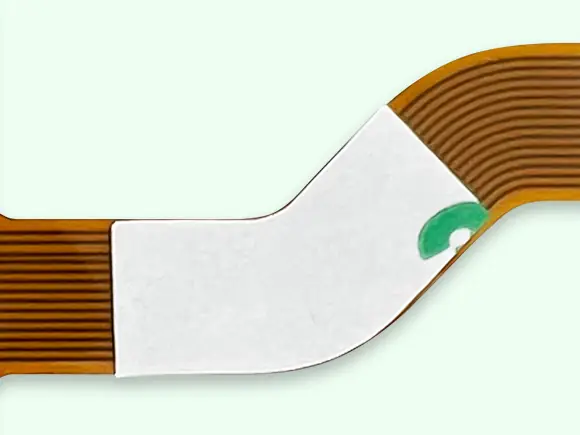

1.5 mm FR4-Stiffener with Silk Print

FR4 stiffeners are available in nearly any shape and thickness – silk print is also possible

Stiffeners can be combined with various technologies: Milling, printing, adhesives, etc. Depending on the size, these stiffeners are assembled with high precision automatically, minimizing misalignment and production time. Typical thicknesses range from 0.3 mm to 2.0 mm, with FR4 used for total thicknesses over 0.5 mm.

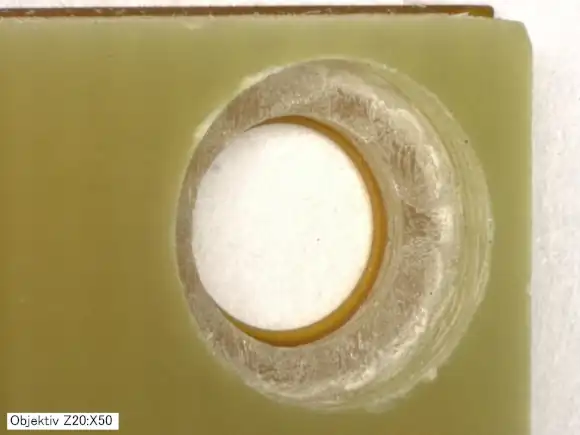

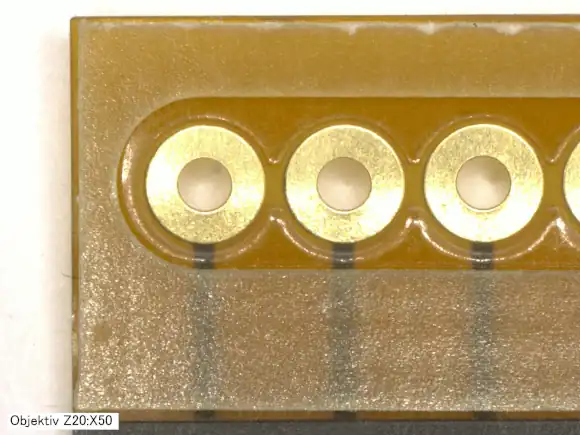

Z-Axis-Milling / Countersink

Depth milling or countersink drilling in stiffeners for optimal screwing

Depth milling creates nearly right-angle recesses, while countersunk holes are conical, allowing screws to sit flush. Edge chamfering is also possible to prevent cracking if flexible parts bend over stiff right-angled FR4 edges.

Shielding Foil

Adhesive shielding foil to protect interference-sensitive areas

Partial shielding foil can be applied to prevent external electromagnetic interference. Placement and shape are flexible, and the foil adapts well due to its flexibility. For double shielding, combining this foil with a copper layer avoids the need for costly 3-layer flexible printed circuits.

0.5 mm Stiffened THT Area

Reinforced THT connector area for stabilization with open solder pads on both sides

Stiffeners are essential for traditional THT connectors to protect solder joints from mechanical stress. Depending on the size and spacing of the solder pads, they can be added in a slot or drilled per pad. It is important that the exposed area is larger than the solder pads.

Half-open PTHs

"Half-opens" with partially open vias on the sides

Half-open but fully plated-through sleeves allow precise soldering of wires or other side contacts. Instead of half-open drill holes, additional outline areas can also be plated through, or special plated slots can be placed within the printed circuit.

Component Stiffener

SMD area stiffening for enhanced component stability and quality

SMD component areas also require stiffeners to prevent detachment under bending stress. Even for non-moving areas, thin stiffeners are recommended to reduce risk during installation.

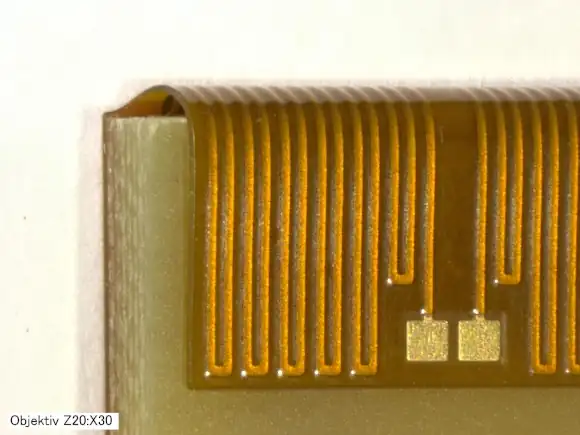

Ultra-Flex-Design

Waveform for ultra-mobile flexibility and stretching in all directions

Flexible "arms" should be designed with snake-like patterns if they need to bend, swivel, and stretch in multiple directions. These designs allow maximum flexibility, but stress is minimized if these areas are kept single-layered. If two layers are necessary, arrange the traces on the top and bottom offset from each other.

"Smart" BOTTOM-Connection

Folded 3M section for economical positioning of components on the FR4 back side

Instead of costly rigid-flex PCBs for a few backside components, these components can be relocated to the bottom side with a "twist". Safety meanders can also be added to prevent unauthorized access to top-side components — the concept of "drill protection."

QR ID-Code Label

100% traceability through QR codes with unique ID on each PCB

Increasing traceability requirements for entire assemblies and components can be met with custom QR or barcodes in various formats and sizes. If desired, information like who processed the PCB at Leiton, the testing results, packaging, and more can be tracked.

FR4-Opening

Open areas in FR4 for bottom contact at any position

An alternative to a "smart" bottom connection is to simply separate the double-sided flexible PCB by opening the stiffener. However, these areas should not be too large to prevent mechanical stress on soldered parts. Caution is advised with component placement in recessed areas.

Cross-Hatch-GND

Cross-hatching on the bottom for shielding with minimal movement restriction

Full ground planes on flexible arms significantly reduce flexibility. Therefore, a "cross-hatch" pattern is often an ideal compromise, providing shielding while maintaining some flexibility. Lower material density also reduces the risk of fatigue and cracking.

0.5 µm Connector Gold

Hard gold thickness of 0.5 to 1.0 µm for increased durability in connection cycles

Partial electrolytic gold can be applied to connectors or within the PCB. When cobalt-doped, this type of gold surface is significantly more durable. The reverse etching process can also be used, where galvanic connections are chemically removed entirely.

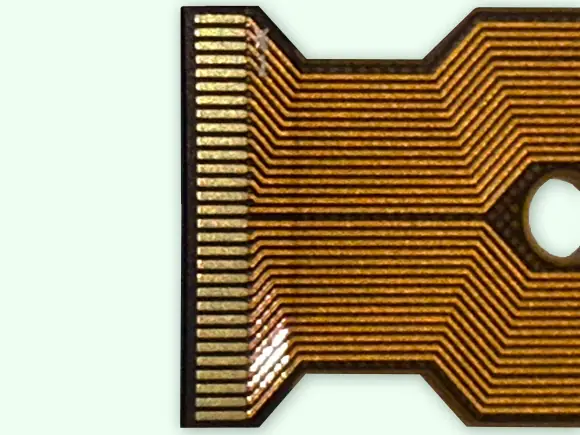

0.3 mm ZIF/LIF Connector Area

Precise overall thicknesses for zero-insertion force / low-force connectors

The standard thickness for ZIF/LIF connector areas is 0.3 mm. For areas from 0.2 to 0.4 mm, a corresponding polyimide film is used to achieve the exact required thickness. Thicker stiffeners are made with FR4, and stainless steel stiffeners are increasingly used for their thinness, strength, shielding, and durability.

3M Adhesive Film

3M double-sided adhesive film for versatile, permanent placement by sticking

3M adhesive films can be applied in any shape and placed on rigid or flexible areas. They are high-temperature resistant for reflow soldering processes and come with an easily removable protective film (liner), allowing for flexible application. The thickness of the 3M film is 50 µm, which should be added to the total thickness.